The company is committed to tailoring a one-stop biodegradable industrial product packaging solution that meets the product characteristics, brand image, environmental goals, and cost considerations of industrial customers. It meets the personalized needs of different brands, markets, and application scenarios. From product structure design, material research and development, mold development to finished product delivery, Hebei Gurui relies on advanced production technology and strict quality control to help customers achieve a dual leap in environmental and commercial value.

In the field of industrial manufacturing, packaging has long been dominated by functionality, often neglecting its deep value. Traditional packaging, although capable of meeting basic physical protection requirements, is increasingly becoming a heavy environmental burden and image shackle on the path of brand sustainable development. Hebei Gurui focuses on the industrial packaging of degradable plant fibers, and deeply understands the complexity and particularity of industrial product packaging. Our industrial packaging solutions meet the requirements for precision, protection and cleanliness in all major industrial fields, and provide customers with excellent alternative solutions beyond traditional plastics, foam (EPS/EPE/ETPU) and corrugated paper partitions.

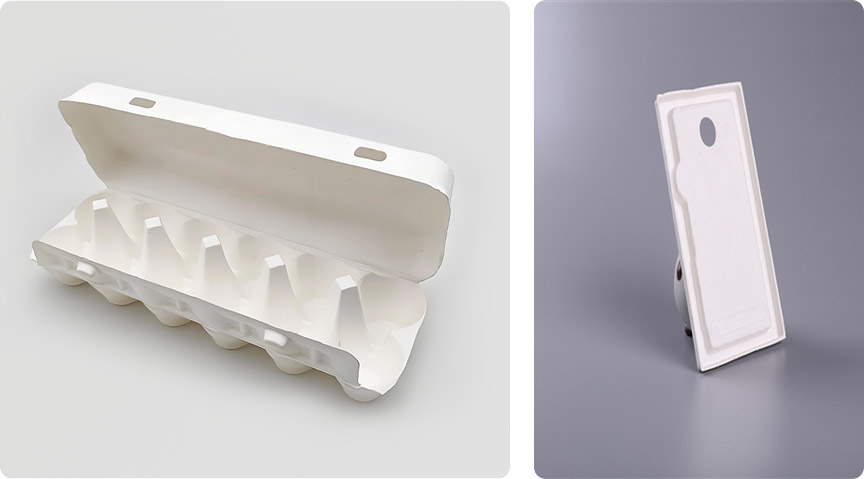

Buffer and anti vibration:By utilizing the unique interlaced network structure of plant fibers, combined with the reinforcement ribs and buffer chambers designed with high-precision molds, the impact and vibration during transportation are effectively absorbed, protecting sensitive components.

Antistatic performance:According to customer needs, anti-static agents can be incorporated into the material formula or anti-static coating technology can be used to meet the anti-static protection standards of passive electronic products.Precise shaping and fixation:The precision of the mold can reach ± 0.1mm, which can perfectly replicate the product contour, ensuring that it can firmly clamp in any posture and prevent displacement and collision.

Dust free and pure: eliminate the dust and fiber chips generated by traditional paper packaging, avoid the risk of chemical volatiles in foam packaging, and provide an ideal internal packaging environment for electronic products with high cleanliness requirements.

Improvement of Aesthetics and Texture:Plant fibers themselves have a warm and elegant touch, and the surface can achieve delicate and smooth or specific texture effects. Through processes such as imprinting logos and patterns, the aesthetic value and unboxing experience of the brand are greatly enhanced.

Extension of brand concept:Using natural and pure plant fibers as packaging, it is highly compatible with the "natural", "healthy", and "organic" concepts advocated by cosmetic brands, achieving consistency in values between products and packaging.

Alien customization capability:Whether it's regular bottles or irregular artistic shapes, perfect fit can be achieved, providing designers with unprecedented creative freedom.

Cleanliness and Safety:The production process goes through multiple disinfection steps such as high-temperature molding and ozone, ultraviolet radiation, etc., resulting in clean and hygienic finished products that are non-toxic and odorless, meeting the environmental purity requirements of auxiliary medical packaging.

Single material easy to recycle:Compared to complex composite material packaging, the use of a single plant fiber material greatly simplifies the post disposal process, meeting the environmental and waste management requirements of medical institutions.